As an important logistics equipment, forklifts are widely used in the fields of cargo handling and storage. Accurately calculating the load capacity of a forklift is key to ensuring safe and efficient operations.

This article will analyze the important parameters of the forklift's load capacity, and introduce how to correctly calculate the load capacity of the forklift, so as to help users better understand and apply these key knowledge.

The load capacity of a forklift refers to the maximum weight it can carry and move safely. Accurately assessing load capacity is critical to ensuring operational safety, preventing equipment damage, and increasing productivity. Knowing the important parameters of load capacity is the basis for correct calculation and evaluation.

Analysis of key parameters

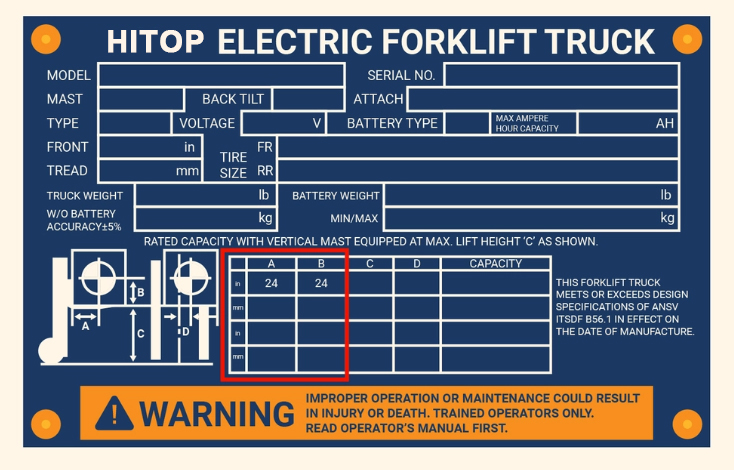

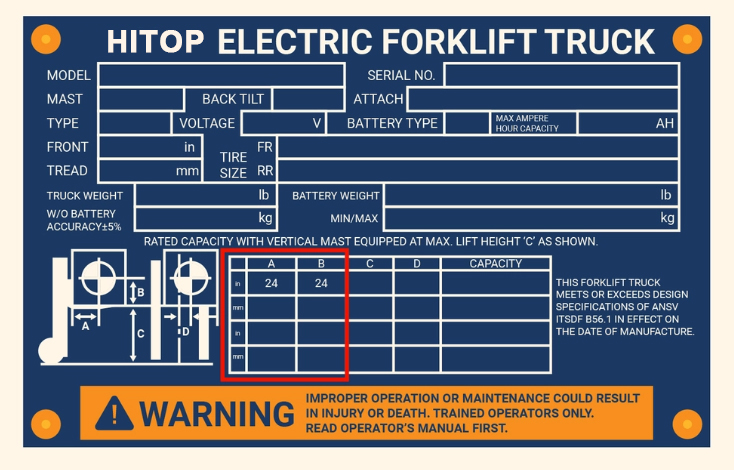

Rated Load Capacity (Rated Load Capacity): The rated load capacity refers to the maximum weight that a forklift can safely carry and carry according to design and manufacturing standards. This parameter is usually indicated on the specification sheet or nameplate of the forklift.

Tare Weight: The weight of the vehicle refers to the weight of the forklift itself, including the frame, engine, cab and other accessories. When calculating the load capacity, the vehicle's own weight needs to be taken into account to ensure safe operation.

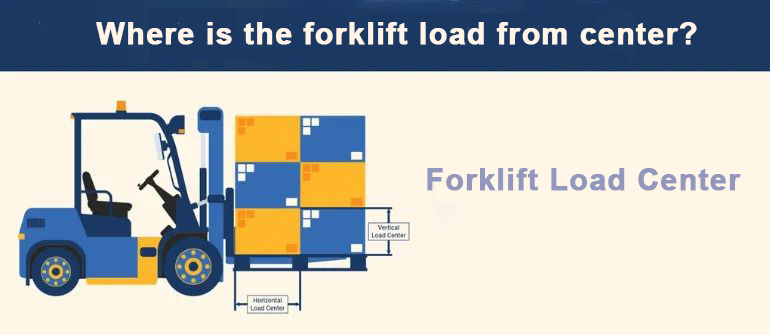

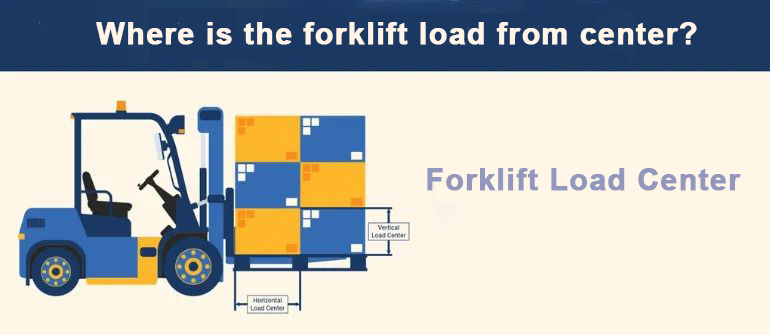

Load Center Distance: The load center distance refers to the distance between the cargo load and the front axis of the forklift. Typically, the load center distance is 24 inches (about 610 mm). But in actual operation, if the center distance of the goods is different, the calculation of the load capacity needs to be adjusted accordingly.

Lift Height (Lift Height): The lift height refers to the maximum height to which the forklift can lift the goods. Forklifts may have different load capacities at different lift heights because the center of gravity of the cargo changes as the lift height increases. Therefore, when calculating the load capacity, the lifting height of the cargo should be considered.

Tilt Angle: Tilt Angle refers to the greater angle at which the forklift can tilt the cargo forward or backward. The angle of inclination also affects the load capacity of the forklift because the center of gravity changes when the load is tilted. When calculating the load capacity, the effect of the angle of inclination on stability and safety needs to be considered.

Steps to Calculate Load Capacity

Determine the rated load capacity of the forklift, which can usually be found on the forklift's specification sheet or nameplate.

Determine the weight of the cargo. If the weight of the shipment is unclear, weighing equipment or other methods of measurement can be used to obtain accurate figures.

Consider the vehicle's own weight, including the frame, engine, cab, and other accessories.

Determine the load center distance of the cargo. The load center distance refers to the distance between the cargo load and the front axis of the forklift.

The standard load center distance refers to the standard load center distance adopted by the forklift manufacturer when designing and evaluating the load capacity, and the default is 24 inches (about 610 mm).

Substitute the above parameters into the appropriate load capacity calculation formula to calculate the exact load capacity of the forklift.

Consider the effect of the lift height and inclination angle of the cargo on the load capacity. Adjust the value of the load capacity according to the actual situation.

The following is a commonly used calculation formula:

Load capacity = (rated load capacity - vehicle weight) + load center distance × cargo weight ÷ standard load center distance

Please note that this is just a common formula for calculating load capacity, and the actual situation may be different. For specific models and manufacturers of forklifts, you should refer to their relevant specification sheets, operating manuals, or consult a professional for accurate load capacity calculations.

Precautions and Safety Tips

Make sure to measure the weight of your cargo accurately to avoid over or under load situations.

Check your forklift's specification sheet or nameplate regularly to ensure it is always operating within its rated load capacity.

During operation, always maintain stability and balance, avoid sharp turns or unbalanced loading.

For special cases, such as high temperature environment, uneven ground or special cargo shape, a reduced load capacity should be considered to ensure safe operation.

Train operators on the calculation of forklift load capacity and the importance of safe operation.

Liquid loads have some particularities compared to solid cargo, causing the following changes:

Movement of the center of gravity of the load

Liquid loads During the operation of a forklift, its center of gravity may change due to fluidity. When the liquid load moves or tilts inside the container, the position of the center of gravity may shift, affecting the stability and load capacity of the forklift.

Fluid instability

The liquid has certain instability in the container, which is easy to cause the liquid to fluctuate or slosh. This may have an impact on the stability of the forklift, especially when driving at high speeds or when stopping suddenly, increasing the risk of overturning.

Leakage and Leakage Considerations

Liquid loads require special attention to leak-proof and leakage issues. Proper container sealing and securing measures are critical to prevent the escape of liquids and avoid damage to operators, equipment and the environment.

Container selection and suitability

Liquid loads require the use of suitable containers for carrying and handling. The design, material and sealing performance of the container should match the properties of the liquid to ensure safe and efficient transportation.

Accurately calculating the load capacity of a forklift is the key to ensuring safe operation and improving work efficiency. By understanding and applying the important parameters of load capacity, including rated load capacity, vehicle weight, load center distance, lift height and tilt angle, the load capacity of the forklift can be correctly calculated and corresponding safety measures taken. Only when the forklift is operated within a reasonable load range can the safe and stable handling of goods be guaranteed.

Forklift Red Zone Warning Light

Forklift Red Zone Warning Light

HITOP CPD20 CPD16 electric forklifts are exported to the Netherlands and Cayman Islands Respectively

HITOP CPD20 CPD16 electric forklifts are exported to the Netherlands and Cayman Islands Respectively

The Basics of Forklift Tire Maintenance

The Basics of Forklift Tire Maintenance

Four 3-ton HITOP diesel forklifts with Mechanical transmission are ready for Indonesia

Four 3-ton HITOP diesel forklifts with Mechanical transmission are ready for Indonesia